Welding TPO membranes : more than a temperature setting

TPO (Thermoplastic Polyolefin) roofing membranes are not new anymore. In fact, they are one of the fastest-growing commercial roofing membranes on the market today. However, not all TPO membranes are the same. Every manufacturer makes its own version of TPO, with its own formulation, product design, and manufacturing process. As a consequence, the quality of the final product and its performance vary a lot.

A high-quality TPO membrane starts with good chemistry. This is essential to engineer the right polymer, which is the backbone of the product. It is the base that allows all the other elements that go into the TPO formula to work together to achieve the desired result. Finding the correct combination of raw materials and a good formulation, enabled by the right polymer, is what good chemistry is all about.

Factors that influence welding performance

TPO is a thermoplastic, so it can be heat-welded. This creates a monolithic roof layer that protects the building from the elements. A common misconception is that welding is just setting up the welding equipment correctly and welding the TPO membranes together. While it is crucial to have the correct welding equipment, power supply, and right temperature setting to achieve a good quality weld, this is not all. The performance and ease of welding also depend on other factors.

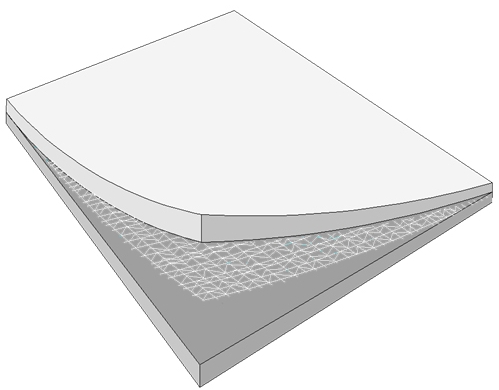

First and foremost, the welding performance of a TPO roofing membrane is highly dependent on how it is made: the product formulation. Most TPO membranes have 3 layers: a top ply, a reinforcement in the middle, and a bottom ply. The top ply is exposed to the elements and needs more additives to achieve the required performance compared to the bottom layer. This means, of course, that these layers are created differently.

It is, therefore, crucial to have the right balance between the top and bottom ply formulation in order to achieve a good welding window, which makes the membrane easy to weld. If that balance is not right, the difference between welding setting requirements for top and bottom ply could be far apart, which could in turn narrow the welding window, making it difficult to find the right welding setting.

The thickness of the top and bottom ply also plays an important role in welding performance. When welding TPO membranes, the welding will be done between the top layer and bottom layer. If one or the other layer does not have enough thickness, it will not be easy to weld the membrane together. Moreover, the strength of the weld will depend on the strength of the thinner, weaker layer.

Another factor that also facilitates the welding of TPO membranes is the color of the top and the bottom ply. If the color difference between the top and bottom ply is not big, when heat is applied, the temperature difference between these 2 layers won’t be much, which will make the welding easier.

In short, the weldability of TPO membranes plays a crucial role in the ultimate performance of a TPO roofing system. All the factors mentioned above should be considered to obtain a good welding result. Elevate's UltraPly TPO roofing membrane is not only durable, its welding aspect is also considered in its construction. It offers a wide welding window which contributes to its ease of installation and the overall superior performance of the whole roofing system.